China wholesale Motor Stator Stamping - Stator&Rotor Lamination For Servo Motor – Gator

China wholesale Motor Stator Stamping - Stator&Rotor Lamination For Servo Motor – Gator Detail:

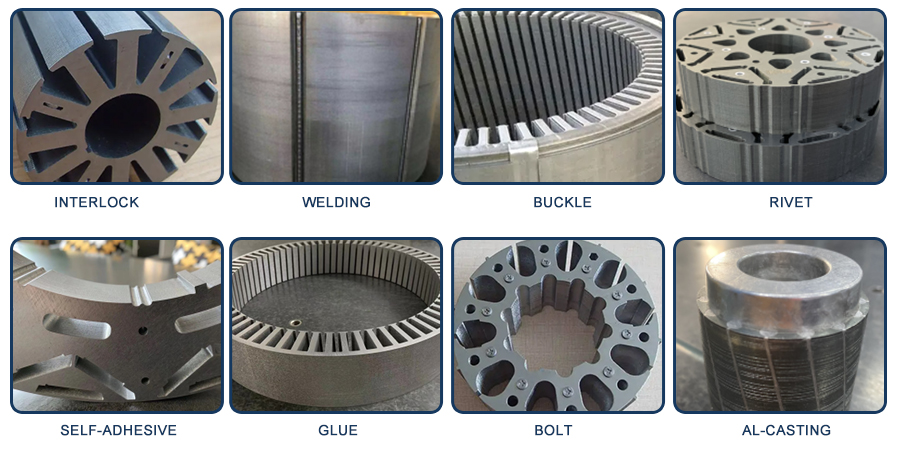

Due to the different requirements of stamping and motor performance, our stator laminations is divided into: interlock, welding, buckle strip, self-adhesive, glued; rotor lamination is divided into: interlock, rivet, self-adhesive, glued, bolt, cast aluminum.

For example: the high-speed stamping motor laminations of the progressive mold will adopt the interlock method, with rectangular and circular lock points respectively. If the Length of the stator laminations exceeds the interlock pull-out force range, we will add an additional amount to the outer diameter with Buckle and welding process reinforcement.

About Backlack material adhesive technology:

The “quick curing” process jointly developed with Baosteel replaces the original welding and riveting process, which can reduce the NVH and iron loss of the driving motor of new energy vehicles and improve the efficiency;The curing time of a single iron core is 4-8min, which is characterized by fast, low cost and short development cycle.

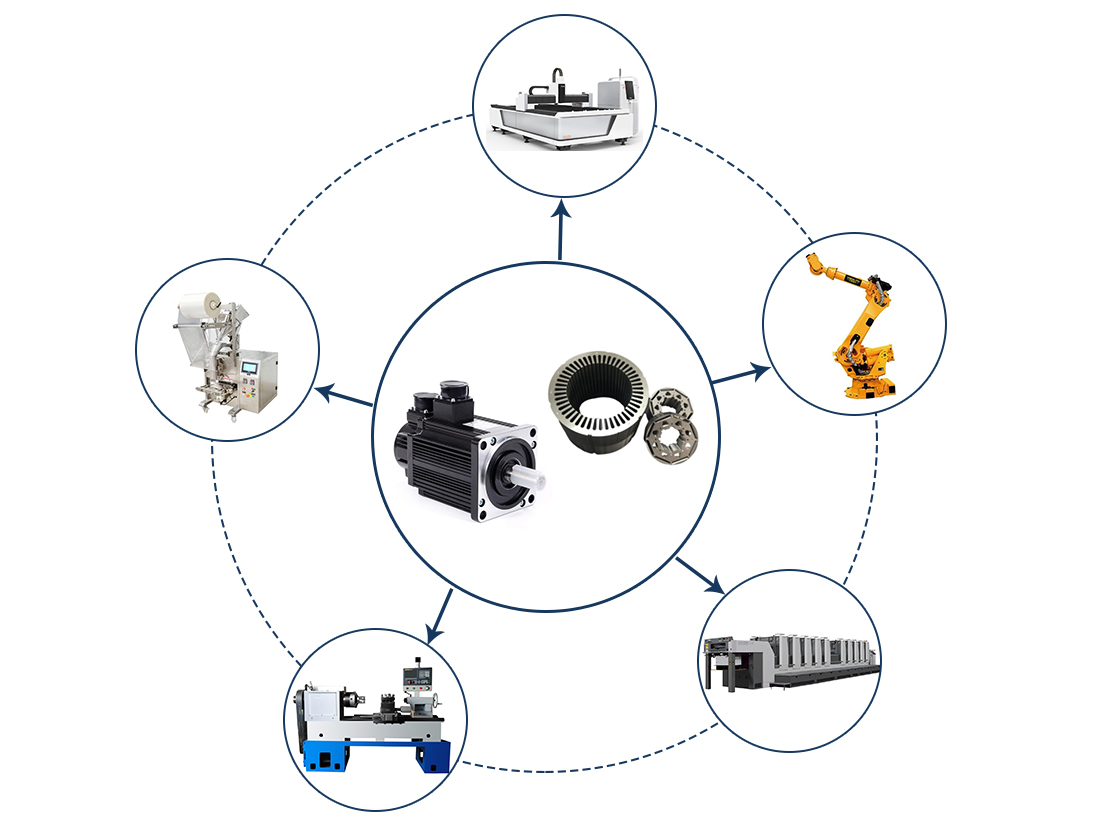

Application of motor laminations for servo motor:

The output power of AC servo motor is 0.1-100W, and the power frequency is 50Hz, 400Hz, etc. It is widely used, such as automatic control, automatic recording and other systems, punch press, printing equipment, laser processing equipment, automatic production line and other equipments with higher requirements for process progress, processing efficiency and work reliability.

DC servo motors can be used in respark machines, manipulators, confidential machines, etc.

In these applications,our motor laminations plays an important role.

Product detail pictures:

Related Product Guide:

We've been commitment to offer the competitive rate ,outstanding merchandise good quality, too as fast delivery for China wholesale Motor Stator Stamping - Stator&Rotor Lamination For Servo Motor – Gator , The product will supply to all over the world, such as: Lithuania, Nepal, Norway, Profession, Devoting are always fundamental to our mission. We have always been in line with serving customers, creating value management objectives and adhering to the sincerity, dedication, persistent management idea.

Place of Origin:Jiangsu, China

Brand Name:OEM & ODM

Material:Silicon Steel sheet

rotor range 10~120mm

Product name:stator & rotor core lamination

Certification:ISO9001、IATF16949

Application:Servo/Reluctance/Transportation/Hydrauli/Elevator/New energy

Usage:DC Motor&AC Motor

Manufacturing Type:Stamping Die

Technical:High Precision

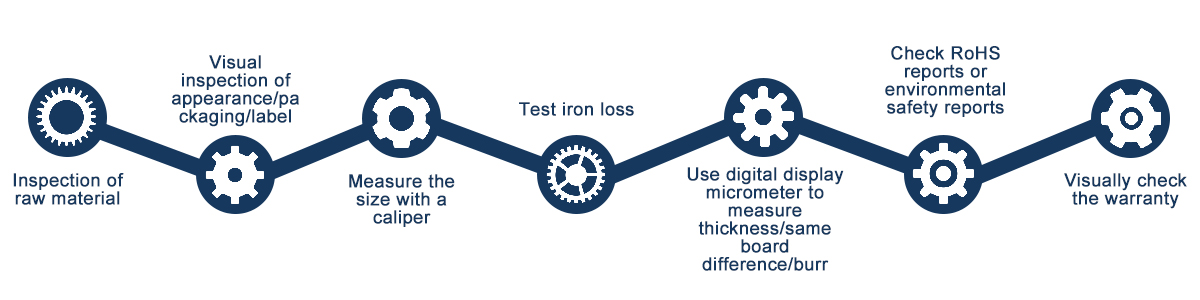

Quality:100% Inspection

Supply Ability:250000 Piece/Pieces per Month

Packaging Details Non-wooden case with pallet

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.