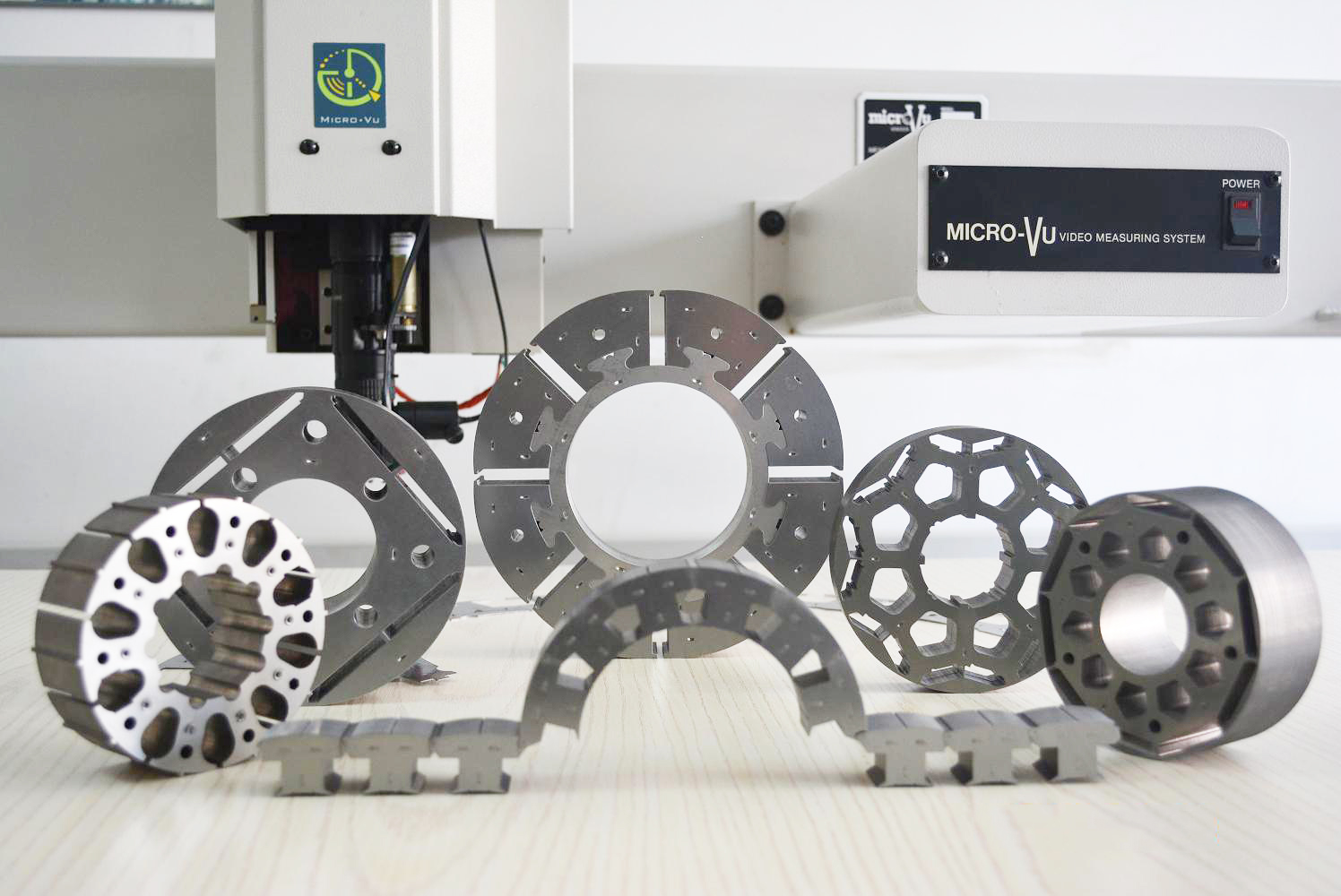

Servo Motor Rotor Lamination

Size:stator range 15~180mm

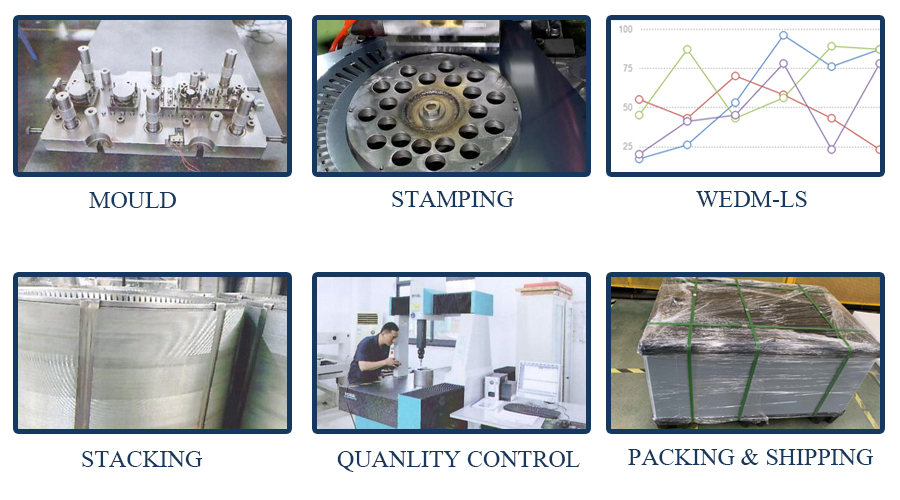

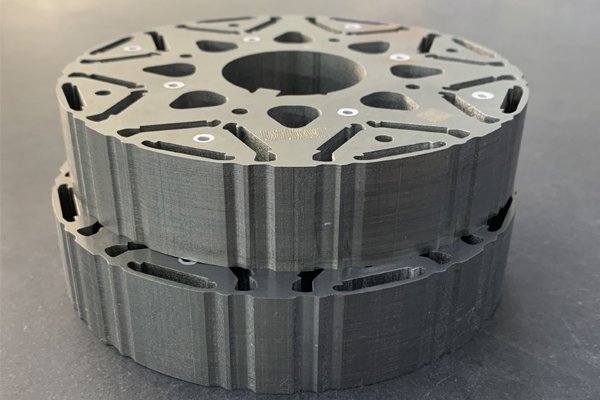

High-precision molds and elbow-type punching automatic production lines are used to complete the stamping manufacturing of various types of servo motor products, which provides greater accuracy and efficiency of iron core products.

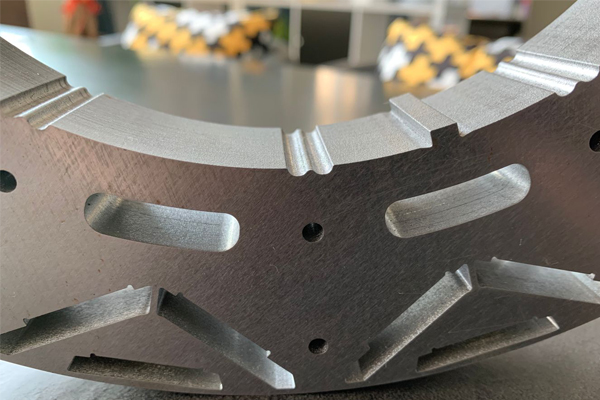

Double-row, four-row, six-row and other rows of stamping are used to make the raw materials, and the utilization rate of raw materials is greatly improved. The rotor core uses pre-blanking and large-turn stamping technology, which makes the thinner structure design of the magnetic isolation bridge possible.

ADVANTAGE

A.Introduced the advanced SCHULER Equipment & Technology from Germany,which let us in the industry leading lever now

B.Achieve batch production of 0.1mm thickness silicon steel and 0.03mm thickness non-alloy material stamping

C.The single slot press can stamp OD2000mm Max

Nanjing university of aeronautics and astronautics into a high speed maglev motor studio

Cooperate with domestic benchmarking enterprises to establish new industry standards

Cross-class industry standards to build benchmark enterprises

Place of Origin:Jiangsu, China

Brand Name:OEM & ODM

Material:Silicon Steel sheet

rotor range 10~120mm

Product name:stator & rotor core lamination

Certification:ISO9001、IATF16949

Application:Servo/Reluctance/Transportation/Hydrauli/Elevator/New energy

Usage:DC Motor&AC Motor

Manufacturing Type:Stamping Die

Technical:High Precision

Quality:100% Inspection

Supply Ability:250000 Piece/Pieces per Month

Packaging Details Non-wooden case with pallet