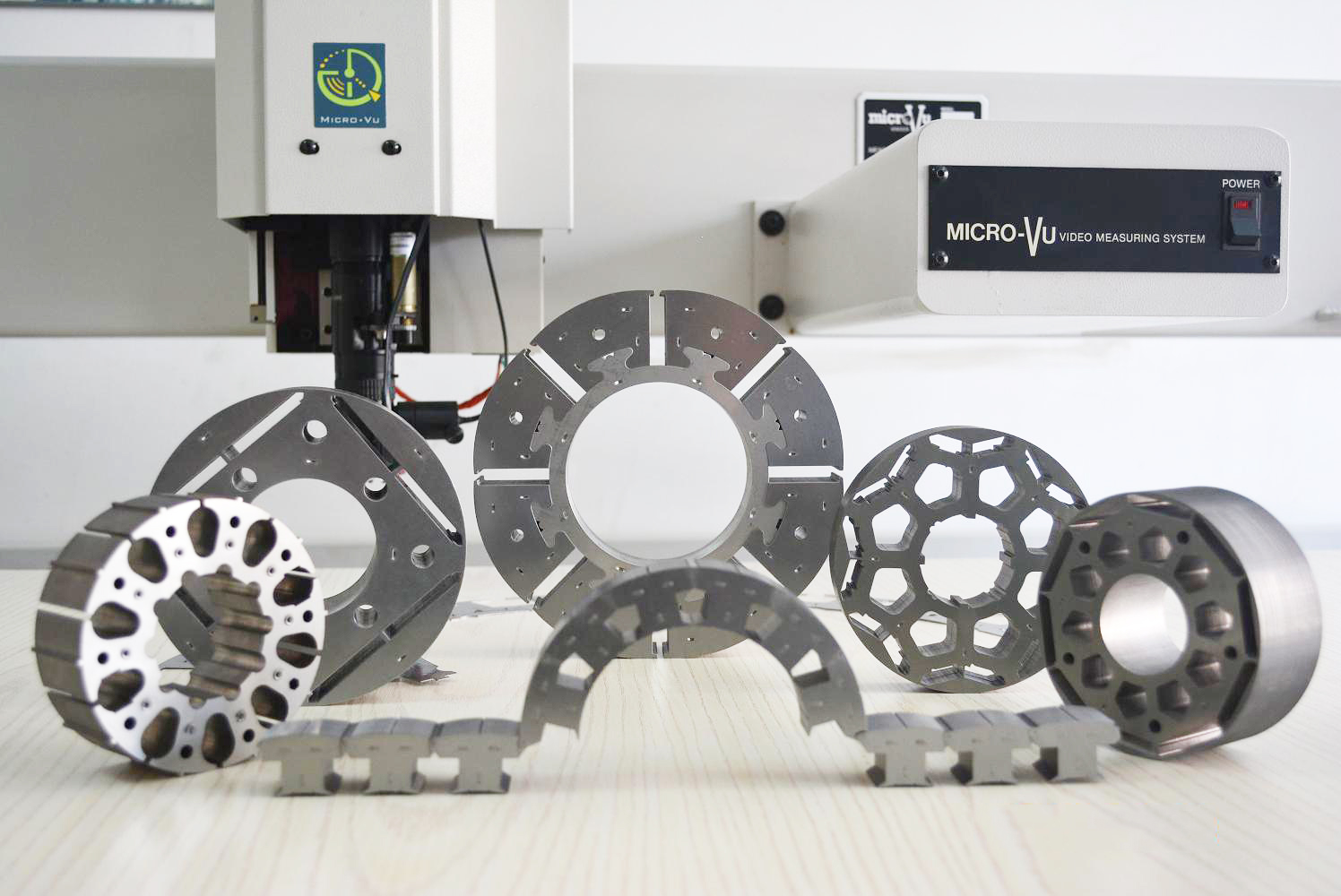

Rotor Stamping For Servo Motor

Size:stator range 15~180mm

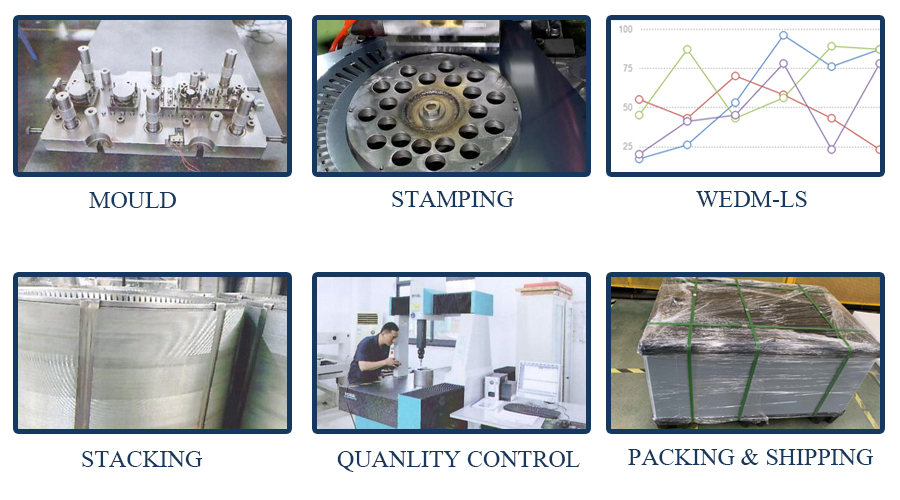

High-precision molds and elbow-type punching automatic production lines are used to complete the stamping manufacturing of various types of servo motor products, which provides greater accuracy and efficiency of iron core products. The stator block iron core can realize round buckle points and square buckle.

We are a one-stop mold solution expert, capable of quality control from beginning to end.

Nanjing university of aeronautics and astronautics into a high speed maglev motor studio

Cooperate with domestic benchmarking enterprises to establish new industry standards

Cross-class industry standards to build benchmark enterprises

Place of Origin:Jiangsu, China

Brand Name:OEM & ODM

Material:Silicon Steel sheet

rotor range 10~120mm

Product name:stator & rotor core lamination

Certification:ISO9001、IATF16949

Application:Servo/Reluctance/Transportation/Hydrauli/Elevator/New energy

Usage:DC Motor&AC Motor

Manufacturing Type:Stamping Die

Technical:High Precision

Quality:100% Inspection

Supply Ability:250000 Piece/Pieces per Month

Packaging Details Non-wooden case with pallet