Stator&Rotor Lamination For Servo Motor

Motor laminations Introduction:

Servo motor is the fastest growth in recent years, the future of the highest prospects, one of the hot market focus of the industry.

This type of stator and rotor stamped by the progressive mold and with the interlock stack technology,which realized in the mold directly.Normally we use BAO STEEL,WU STEEL etc the famous brands electrical silicon material to make sure the stacks with perfect tolerance and performance.

We have different tonnage punch machines to meet different diameters requesment,such as 80T,160T,300T,400T,550T,630T.

Some for the high length stator lamintations ,beside interlock,we adopt the buckles or welding on the out diameter to strength it again.

95% of these products customized.At the beginning of the testing period,we can provide the Motor laminations samples by laser cutting or wire cutting.

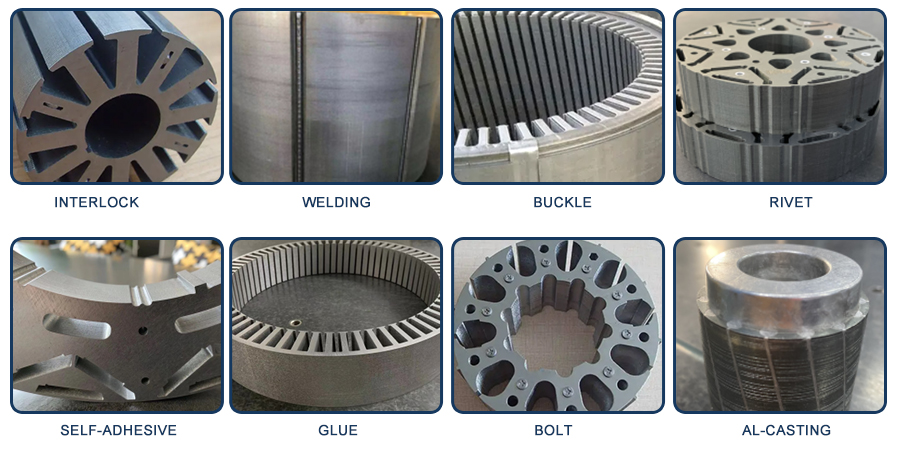

Due to the different requirements of stamping and motor performance, our stator laminations is divided into: interlock, welding, buckle strip, self-adhesive, glued; rotor lamination is divided into: interlock, rivet, self-adhesive, glued, bolt, cast aluminum.

For example: the high-speed stamping motor laminations of the progressive mold will adopt the interlock method, with rectangular and circular lock points respectively. If the Length of the stator laminations exceeds the interlock pull-out force range, we will add an additional amount to the outer diameter with Buckle and welding process reinforcement.

About Backlack material adhesive technology:

The "quick curing" process jointly developed with Baosteel replaces the original welding and riveting process, which can reduce the NVH and iron loss of the driving motor of new energy vehicles and improve the efficiency;The curing time of a single iron core is 4-8min, which is characterized by fast, low cost and short development cycle.

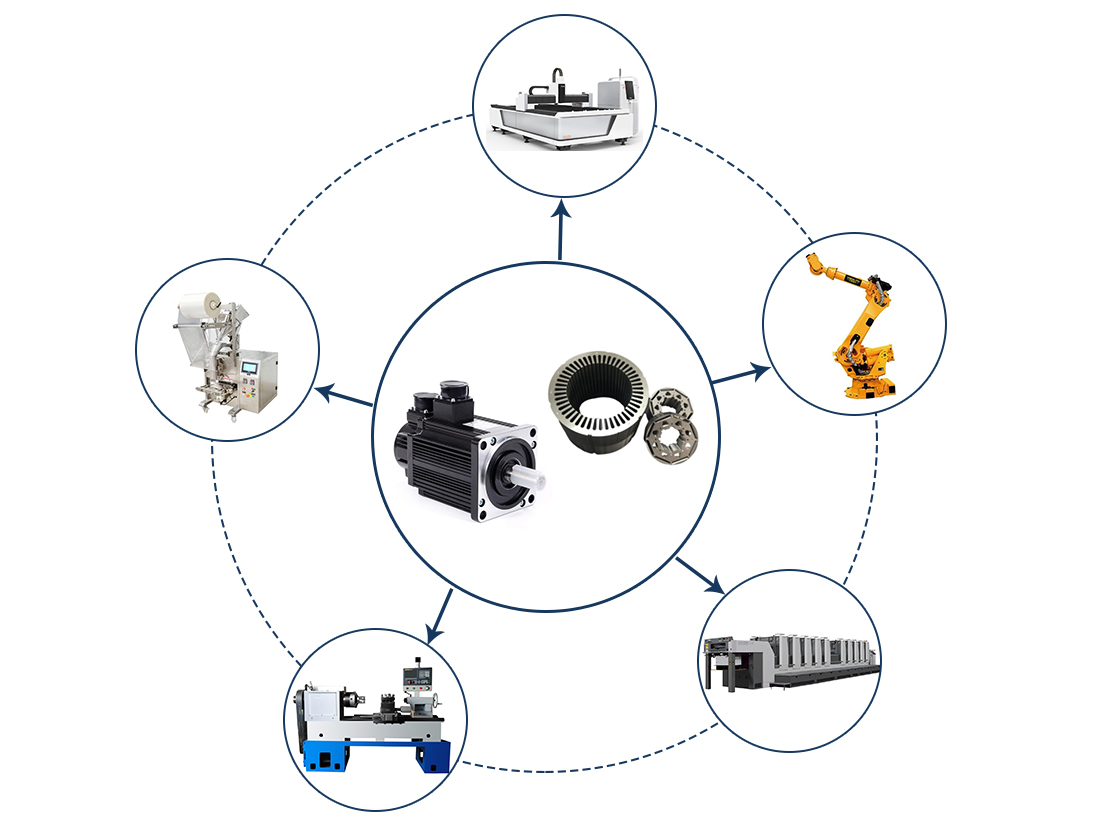

Application of motor laminations for servo motor:

The output power of AC servo motor is 0.1-100W, and the power frequency is 50Hz, 400Hz, etc. It is widely used, such as automatic control, automatic recording and other systems, punch press, printing equipment, laser processing equipment, automatic production line and other equipments with higher requirements for process progress, processing efficiency and work reliability.

DC servo motors can be used in respark machines, manipulators, confidential machines, etc.

In these applications,our motor laminations plays an important role.

Place of Origin:Jiangsu, China

Brand Name:OEM & ODM

Material:Silicon Steel sheet

rotor range 10~120mm

Product name:stator & rotor core lamination

Certification:ISO9001、IATF16949

Application:Servo/Reluctance/Transportation/Hydrauli/Elevator/New energy

Usage:DC Motor&AC Motor

Manufacturing Type:Stamping Die

Technical:High Precision

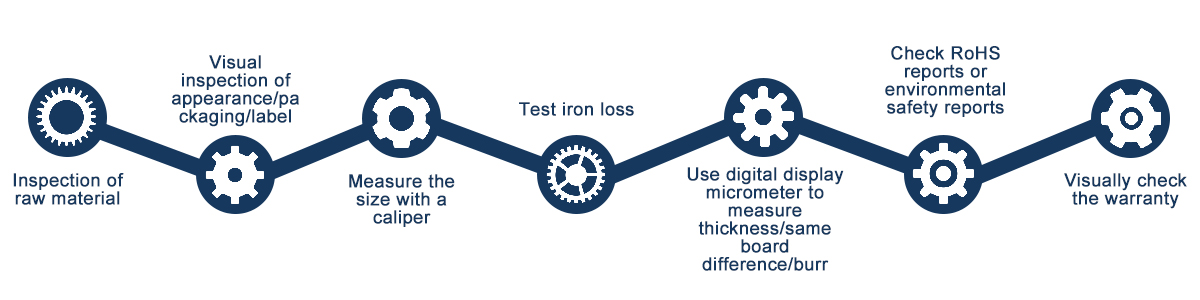

Quality:100% Inspection

Supply Ability:250000 Piece/Pieces per Month

Packaging Details Non-wooden case with pallet